3D fence panel manufacturing

On October 16, 2025, Giant Fence’s powder coating workshop was bustling with activity. The production line was busy processing 3D fence panels, posts, and clips, all coated in the classic green RAL6005 – a popular shade for both residential and commercial fencing projects.

Rows of 3D fence panels moved steadily through the newly upgraded fully automatic powder coating line. This advanced system ensures uniform coating thickness and a smooth, durable surface finish, significantly improving corrosion resistance and long-term performance in outdoor environments.

3D fence panel manufacturing

3D fence panel powder coating

Under the workshop lights, the green-coated panels showcased the precision and efficiency of the modern coating technology. Compared to traditional manual operations, the automated system enhances production consistency, minimizes waste, and optimizes energy usage – reflecting Giant Fence’s commitment to sustainability and innovation.

3D Fence panels powder coating

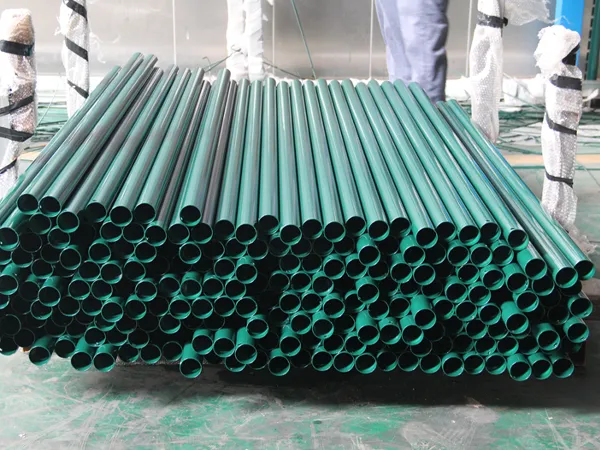

Post powder coating

This on-site production highlights not only Giant Fence’s manufacturing capabilities but also its continuous investment in technology upgrades. By modernizing its powder coating line, the company strengthens its ability to deliver high-quality fencing solutions to clients worldwide.

Every 3D fence panel produced on that day demonstrates Giant Fence’s dedication to detail, quality, and customer satisfaction, ensuring each product meets the highest international standards.

If you have any doubts, just feel free to contact us, we are ready to serve for you.