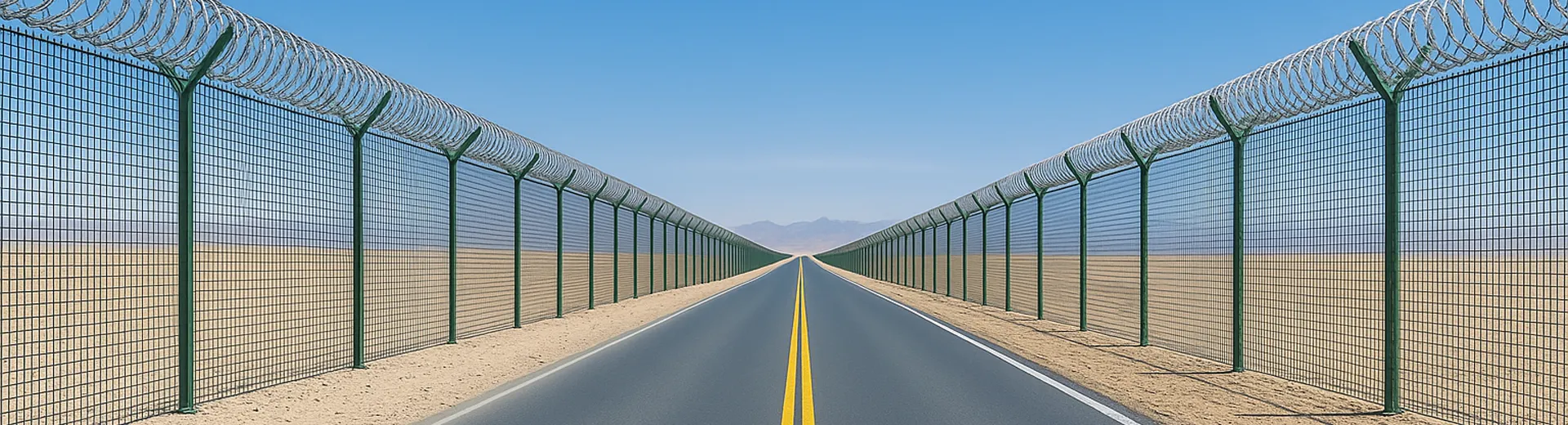

- Home

- Product

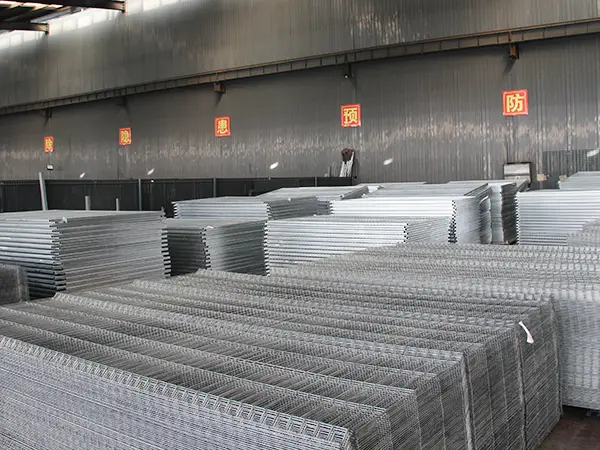

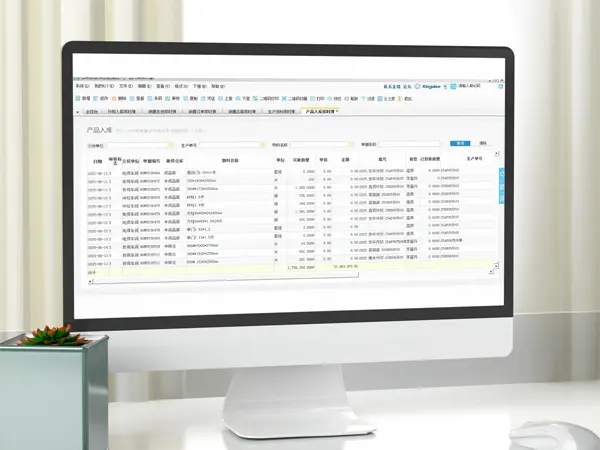

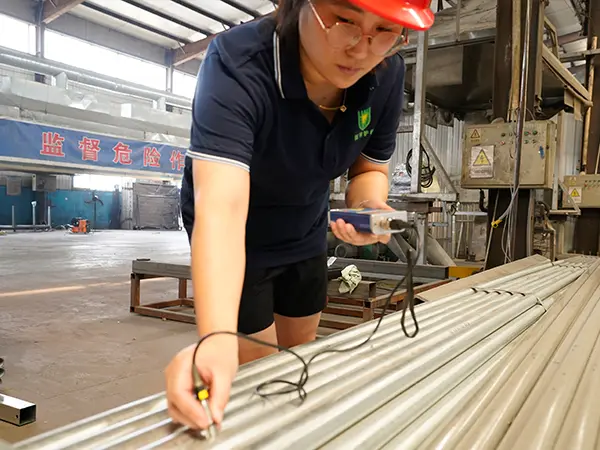

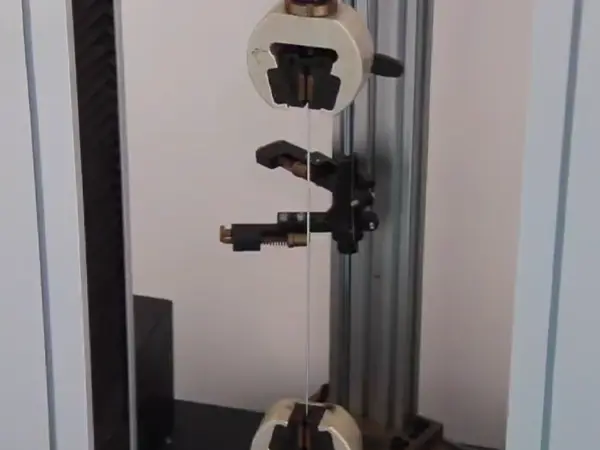

- Factory Tour

Factory Tour

Factory TourStep inside our real production site — through photos, videos, and VR — and see our capabilities firsthand.

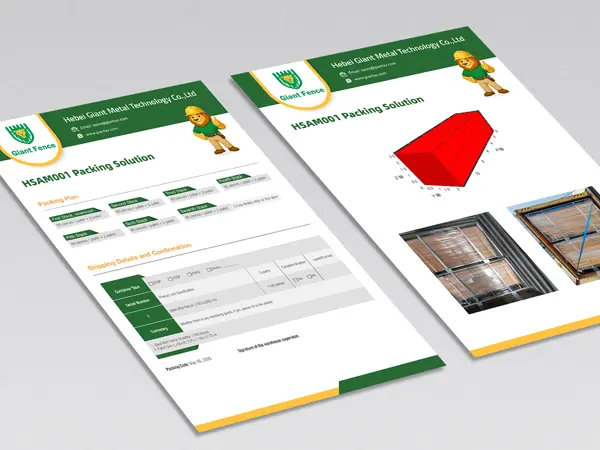

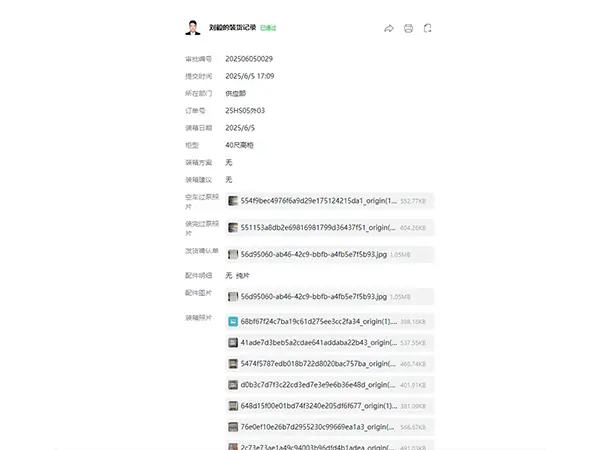

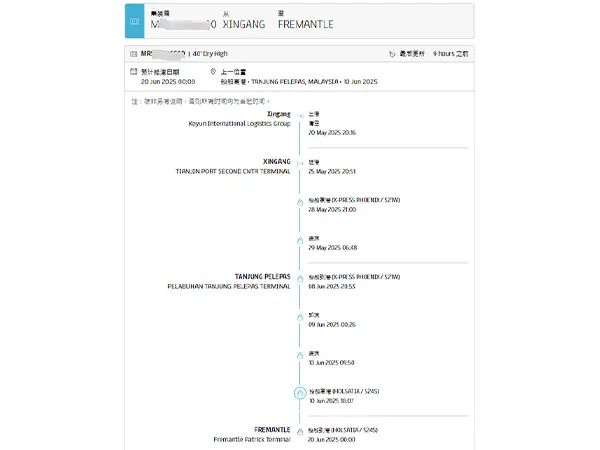

- Case Study

- Resources

Resources

ResourcesAccess technical guides, downloads, and quotation tools to support your fencing project with confidence.

- About

About

AboutDiscover who we are, what we stand for, and why global clients trust us as their fencing partner.

- Contact

Search